mRNA is once again sparking worldwide attention for its immense possibilities. It not only gave us a breakthrough vaccine to fight COVID-19—thanks to the Nobel Prize-winning work of scientists Katalin Kariko and Drew Weissman—but its future applications, especially in drug development, have even greater potential to prevent and treat some of the world’s most critical health challenges, from malaria and cancer to rare genetic disorders.

“The potential for RNA-based medicines is astonishing,” said Scott Ripley, General Manager for Nucleic Acid Therapeutics at Cytiva, a Danaher operating company. “mRNA therapies can target specific cells, encode proteins and trigger immune responses, enabling its use in vaccines and cell and gene therapies. We’re only scratching the surface of what’s possible.”

But while the life-saving potential of mRNA applications is abundant, the necessary biomolecule is scarce – at least at the high quality needed for clinical use. Because of the complexity it takes to produce and encapsulate mRNA into lipid nanoparticles (LNPs)—the protective wrapper that helps stabilize mRNA for safe delivery into the body—the production process is typically siloed and costly. Pharmaceutical companies can either outsource with multiple contract development and manufacturing organizations (CDMOs) or handle each step in-house. Both options, however, are often wildly impractical for most pharma companies—start-up, global or otherwise. Outsourcing to multiple providers is expensive and time consuming, while insourcing requires extensive manufacturing expertise.

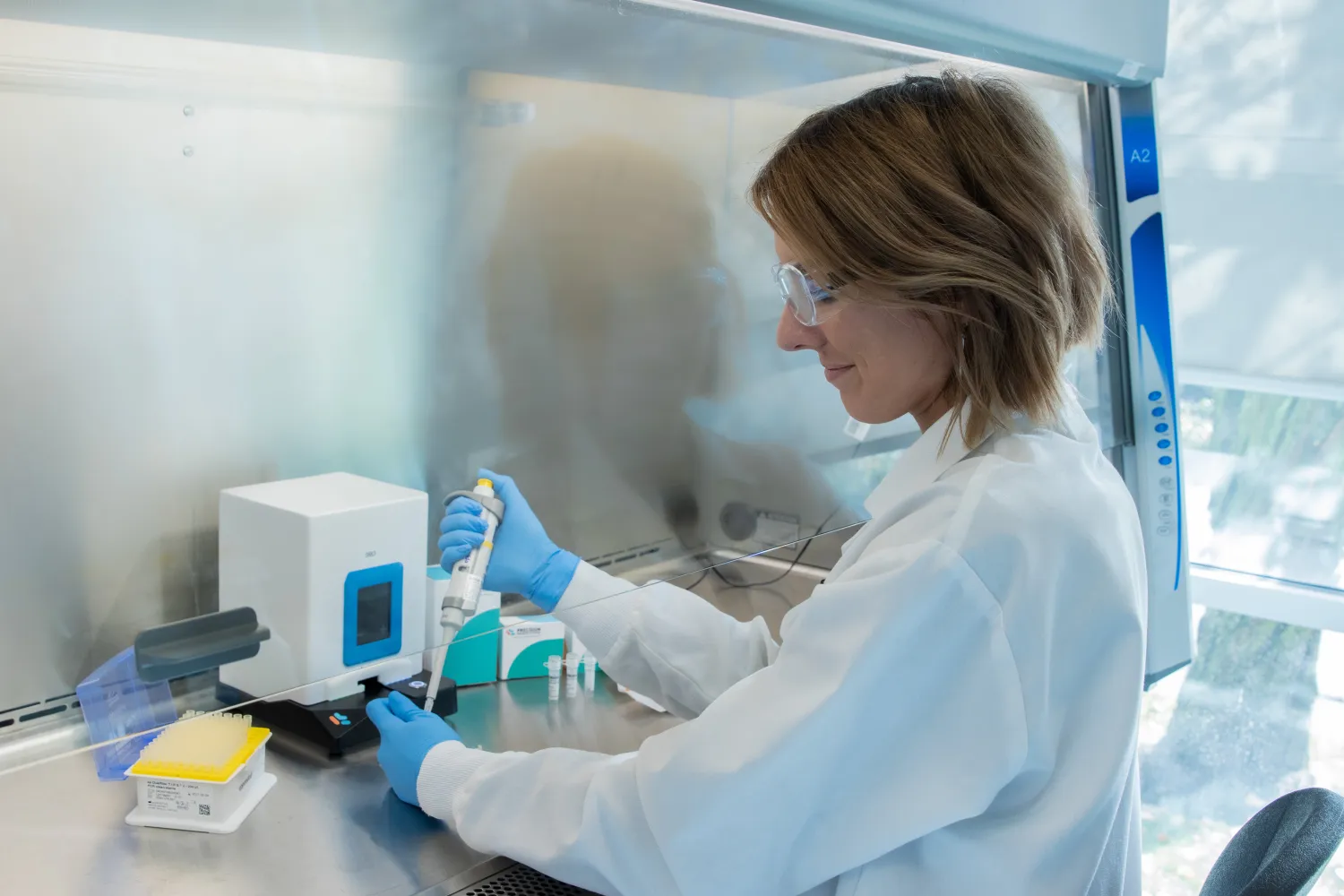

"mRNA isn't easy to manufacture—the potential for human error is great during production and it becomes even more precarious when dealing with multiple vendors," said Dr. Venkata Indurthi, Chief Scientific Officer at Aldevron. "The points of friction that occur can impact tech transfer, create bottlenecks and increase costs, delaying prospective therapies from getting to market."

That’s why Aldevron and Cytiva—together with their parent company, Danaher—created a comprehensive mRNA production ecosystem in 2023. The solution houses sequence-to-vial capabilities under one roof, enabling Danaher to meet customers’ mRNA needs across a range of size and scale.

“By housing our collective capabilities under one umbrella, we’re reducing the cost and complexity of drug development so customers can concentrate on the ambitious problems they’re trying to solve,” said Ripley.